What you need to know to be a CNC Programmer?

Job availability for CNC Programmers

How much can a CNC Programmer make?

Why learn how to use CAM Software?

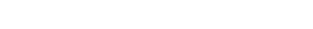

What you need to know to be a CNC Programmer

The following chart is courtesy of www.study.com and provides a brief overview of what is required to become a CNC Programmer.

Visit the following link to get more information. Click here to go to study.com's "Become a CNC Programmer Education and Career Roadmap"

Job availability for CNC Programmers

Job Prospects and Pay for people in Manufacturing

Click here to download the State Manufacturing Data Table

Job Prospects and Pay for people in CNC Programming

CNC Programmer Salaries in United StatesThe national average salary for a CNC Programmer is $54,588 in United States. Filter by location to see CNC Programmer salaries in your area. Salary estimates are based on 237 salaries submitted anonymously to Glassdoor by CNC Programmer employees.

CAM Salaries in United States

The national average salary for a CAM is $40,558 in United States. Filter by location to see CAM salaries in your area. Salary estimates are based on 49 salaries submitted anonymously to Glassdoor by CAM employees.

Certification/Credentials

For more information on the Mastercam Certification and Credentials proceed to the following link:

Check out the different Certification options for Mastercam.

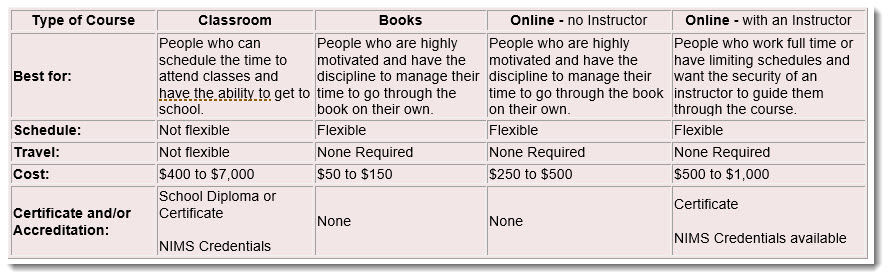

Classroom vs Book vs Online

Features of a good course

All good courses use the following strategies so students will have the best opportunity to learn the theory and skills required to meet the demands of the working world;

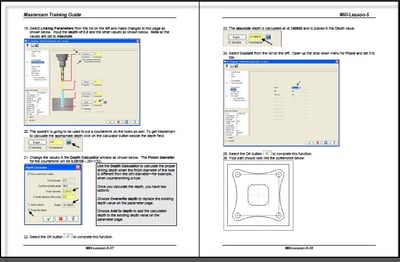

Theory-reading, watching and listening to required information. This can include easy to follow step by step instructions in the form of written supported by video content.

Practical hands-on projects and exercises. Providing lessons that are realistic motivates learning. When teaching future CNC Programmers how to use Mastercam feedback from teachers state that interesting projects (lessons) facilitate learning. "Students are learning Mastercam at a pace that even surprises the teacher".

We have sample lessons in our camInstructor Resource Hub, check them out.

Feedback –Quizzes and Tests should be included in the content in order to provide instant feedbac k to students once they have learned the material. It is preferable that some of the quizzes and tests are automatically marked by the system being used so students can get instant feedback on their work.

k to students once they have learned the material. It is preferable that some of the quizzes and tests are automatically marked by the system being used so students can get instant feedback on their work.

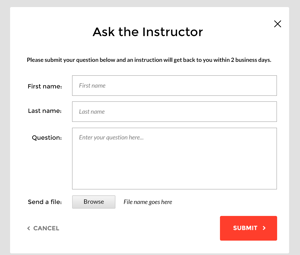

It is also recommended that when possible an Instructor be available to answer questions and provide feedback on practical tests. Look for an online course that offers access to an Instructor for the duration of the course.

The ultimate test to know if learning has taken place in a CNC Programming Course and when learning Mastercam is that the student can draw, toolpath and create the NC code that will run CNC Machine and make an accurate part with the time and tolerance outlined by the Test.

To learn how camInstructor provides these requirements, check out the online course page.

Why learn how to use CAM Software?

Manufacturing complexity.

The manufacturing environment is increasingly complex. The need for CAM and PLM tools by the manufacturing engineer, NC programmer or machinist is similar to the need for computer assistance by the pilot of modern aircraft systems. The modern machinery cannot be properly used without this assistance.

Today's CAM systems support the full range of machine tools including: turning, 5 axis machining and wire EDM. Today’s CAM user can easily generate streamlined tool paths, optimized tool axis tilt for higher feed rates, better tool life and surface finish and optimized Z axis depth cuts as well as driving non-cutting operations such as the specification of probing motions.

Why learn Mastercam?.jpg?width=288&name=Mastercam%20CIMData%202017%20(lo%20res).jpg)

Your chances increase when you know how to use the most popular Software in your industry.

Experts agree that knowing how to use the most popular software product in your industry is the smart approach to finding employment.

.png?width=190&name=logo%20(1).png)

.png?width=190&name=logo-white%20(1).png)